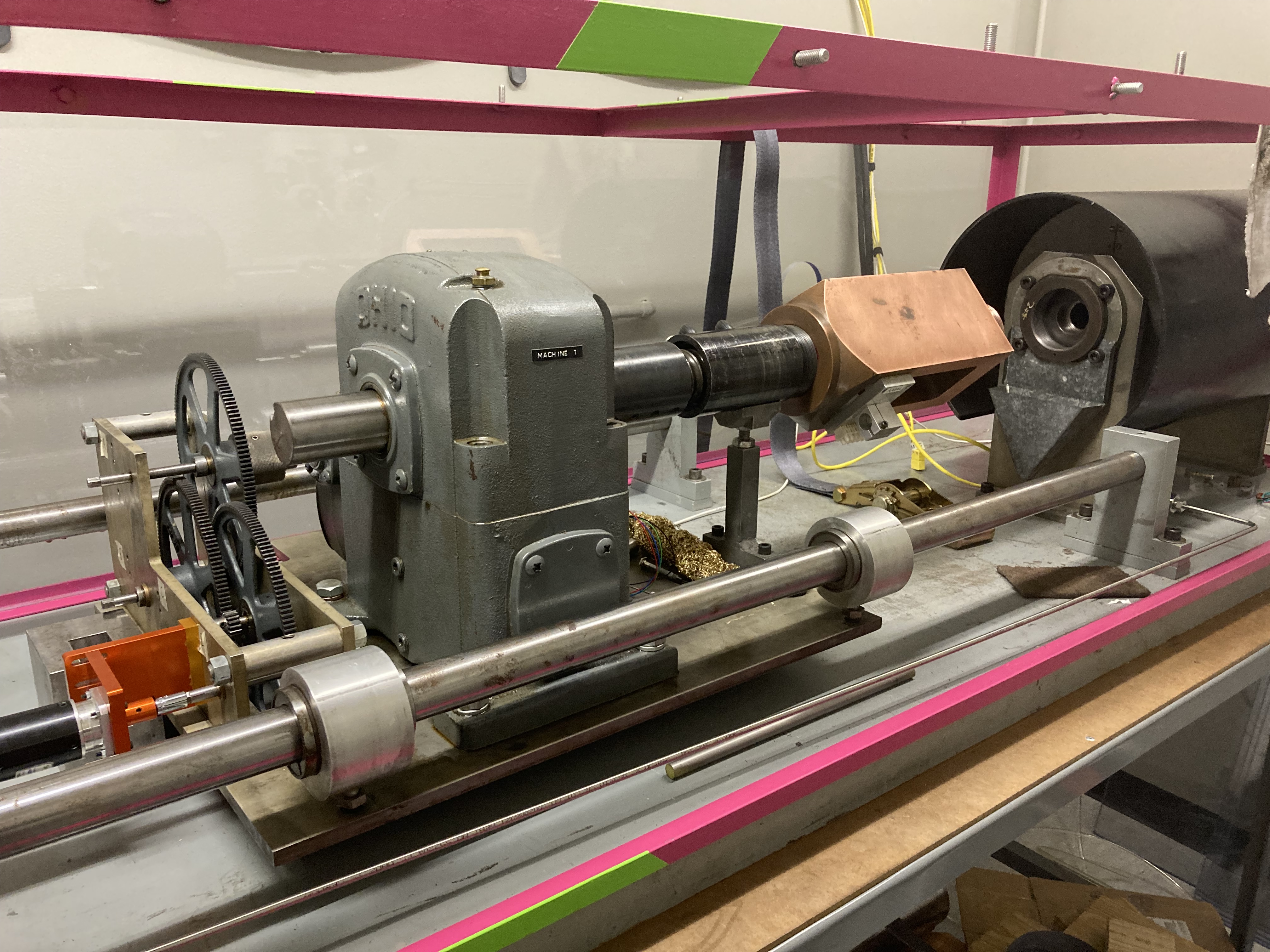

Heard Apparatus

A gear-driven triaxial apparatus inherited from John Logan. This apparatus is externally-heated and uses a high-temperature heat transfer fluid as the confining medium, allowing for experiments up to 400oC. It is also equipped with a single-sided pore-pressure system so that pore fluid volume and pressure can be continuously monitored. A semi-internal load cell eliminates the effect of seal friction on mechanical results. Data collection via LabView program produced by Leeman Geophysical.

Limits:

- Confining pressure: < 210 MPa

- Pore fluid (H2O) pressure: < 210 MPa

- Temperature: 20 – 400oC

- Differential load: < 100 kN

Experiment types:

- Triaxial deformation

- Frictional sliding

- Hot pressing

Notable capabilities:

- conduct experiments at temperatures up to 400oC

- maintain constant normal stress during frictional sliding

- measure in-situ permeability using pulse-decay method

GCTS RTR 2000 Triaxial Apparatus

A hydraulic-driven, servo-controlled triaxial apparatus produced by GCTS. The apparatus is externally-heated and uses silicone oil as the confining medium. It has a two-sided pore-pressure system, which allows for independent control of pore fluid pressures and/or volumes on each side of the sample. We can switch between multiple internal load cells to maximize the sensitivity of load readings. The apparatus includes integrated digital signal conditioning and data collection and apparatus control use state-of-the-art CATS software provided by GCTS.

Limits:

- Confining pressure: < 210 MPa

- Pore fluid (H2O) pressure: < 210 MPa

- Temperature: 20 – 200oC

- Differential load: < 2000 kN

Experiment types:

- Uniaxial or triaxial deformation

- Frictional sliding

- True-triaxial deformation

Notable capabilities:

- measure sample-scale radial and axial strain with internal sensors

- conduct ultrasonic wavespeed measurements throughout deformation

- quantify flow-through permeability in-situ with high precision pore-pressure system

- experiments can be run for weeks at a time

ATS 2330 Lever Arm Tester

A high-temperature uniaxial creep apparatus. Load is applied to the sample by a 20:1 lever arm. The apparatus is equipped with a pull-to-push fixture, allowing for compressional deformation. A three-zone clamshell furnace surrounds the pull-to-push fixture, ensuring the sample remains at a stable prescribed temperature. Shortening of the sample is measured by a high-precision spring-loaded extensometer. WinCCS software provided by ATS facilitates apparatus control and temperature and displacement data collection.

Limits:

- Temperature: 20 – 1100oC

- Axial load: < 9 kN

Experiment types:

- Constant load

- Uniaxial hot pressing

Notable capabilities:

- conduct experiments at temperatures up to 1100oC

- designed for creep experiment durations on the order of weeks

Updated February 2026

Designed with WordPress